EXECUTIVE SUMMARY

I.

Introduction

This

is the 7th Monthly EM&A Report prepared by Fugro Technical

Services Limited for the Contract no. HY/2018/08 Central Kowloon Route �V

Central Tunnel. The Contract no. HY/2018/08 commenced on 19 September 2019. This

report summarized the monitoring results and audits findings of the EM&A

programme under the issued EP (EP No.: EP-457/2013/C) and in accordance with

the EM&A Manual during the reporting period from 01/03/2020 to 31/03/2020.

II.

Summary of Main Works Undertaken and Key Measures Implemented

The

main construction works carried out in the reporting period were as follow:

�P

Prebored H piling for ventilation shaft;

�P

Formation of site haul road leading to Chung Hau Street;

�P

Drill and Blast excavation for construction adit;

�P

Mucking out from tunnel;

�P

Construction of spoil basin;

�P

Site installation and utilities diversion;

�P

Erection of blast doors at construction adits;

�P

Removal of oversize tree T143;

�P

Trial grouting.

III.

Summary of Exceedances, Investigation and Follow-up

No

Action and Limit Level exceedance was recorded for construction dust monitoring

in the

reporting

month. No Limit Level exceedance was recorded for construction noise monitoring

in

the

reporting month.

Three

(3) Action Level exceedances were recorded for construction noise due to the

noise-related complaints received in the reporting month.

IV.

Complaint Handling, Prosecution and Public Engagement

Three (3) noise-related complaints were received respectively on

17, 27 and 31 March 2020 via the complaint hotline of the Contract, and ET was

notified of these complaints on 8 April 2020. The complaint cases are under

investigated and the investigation results will be reported in the subsequent

Monthly EM&A Report.

No

notification of summons and prosecutions were received in the reporting period.

No

public engagement activities were conducted in the reporting period.

V.

Reporting Change

There

were no reporting changes during the reporting month.

VI.

Future Key Issues

The

main works will be anticipated in the next reporting period are as follow:

�P

Formation of site haul road

leading to Chung Hau Street;

�P

Drill and Blast excavation for

construction adit;

�P

Mucking out from tunnel;

�P

Construction of spoil basin;

�P

Erection of blast doors at

construction adits;

�P

Site installation and utilities

diversion;

�P

Removal of oversize tree T143;

�P

Trial grouting.

The recommended

mitigation measures corresponding to the main works in the next reporting

period are listed as follow:

�P

Mitigation measures in form of regular watering under a good site

practice should be adopted, particularly for the earthwork and breaking activities;

�P

Any excavated, stockpile of dusty material or load of dusty

materials on a vehicle leaving a construction site should be covered entirely

by impervious sheeting;

�P

All construction plants / machineries should be checked / serviced

on a regular basis during the courses of construction to minimize the emission

of noise generation and eliminate dark smoke emission;

�P

All C&D materials generated should be transported and stored at

temporary storage area. Suitable materials should be sorted for reuse on-site;

�P

Wastewater generated from drilling shall be properly collected for

reuse or treated by wastewater treatment facilities before discharge;

�P

Provision of drip trays for equipment likely cause spillage of

chemical / fuel, and provide routine maintenance;

�P

Erecting temporary noise barrier for noisy Powered Mechanical

Equipment (PME) and deployment of Quality Powered Mechanical Equipment (QPME)

as many as practicable;

�P

Mitigation measures recommended in the Landscape Mitigation Plan

shall be implemented for felling trees;

�P

Conditions in the Environmental Permit and License should be

followed;

�P

All recommended mitigation measures specified in the approved EIA

Report and EM&A Manual shall be implemented.

The

following EP submissions (EP-457/2013/C) were submitted during the reporting

month:

Table I Status of Required

Submission under Environmental Permit

|

EP Condition

|

Submission

|

Submission Date

|

|

3.4

|

Monthly EM&A Report (February 2020)

|

13 March 2020

|

Contents

1.1 Background 1

1.2 Project Organization 2

1.3 Construction Programme and Activities 2

1.4 Works undertaken during the month 2

1.5 Status of Environmental Licences, Notification and Permits 2

2.1 Construction Dust and Noise Monitoring Location 3

2.2 Construction Dust Monitoring 3

2.3 Construction Noise Monitoring 5

2.4 Construction Dust and Noise Monitoring Schedule 7

2.5 The Action and Limit Levels 7

2.6 Landscape and Visual 7

3.1 Construction Dust Monitoring 8

3.2 Construction Noise Monitoring 8

3.3 Waste Management 9

3.4 Landscape and Visual 9

5.1 Complaint Handling, Prosecution and Public Engagement 11

5.2 Summary of Environmental Non-Compliance 11

Tables

Table

I �V Status of Required Submission under Environmental Permit ii

Table 1.1 �V Contact Information of Key Personnel 2

Table 1.2 �V Environmental Licenses, Notification

and Permits Summary 2

Table 2.1 �V Construction Dust and Noise

Monitoring Location 3

Table 2.2 �V Construction Dust Monitoring

Equipment 3

Table 2.3 �V Construction Noise Monitoring

Parameters, Frequency and Duration 6

Table 2.4 �V Construction Noise Monitoring

Equipment 6

Table 3.1 �V Summary of 1-hour TSP Monitoring

Results in the Reporting Period 8

Table 3.2 �V Summary of 24-hour TSP Monitoring

Results in the Reporting Period 8

Table 3.3 �V Summary of Construction Noise

Monitoring Results in the Reporting Period 8

Table 4.1 �V Observations and Recommendation of

Site Inspection in the Reporting Period 10

Table 6.1 �V Status of Required Submission under

Environmental Permit 12

Figures

Appendices

1.

INTRODUCTION

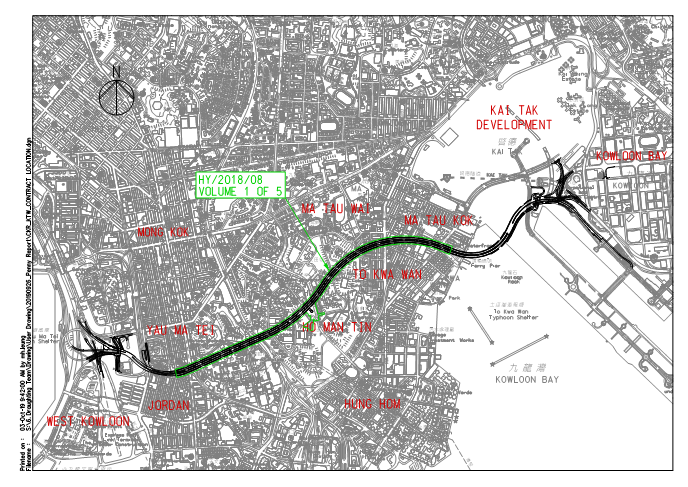

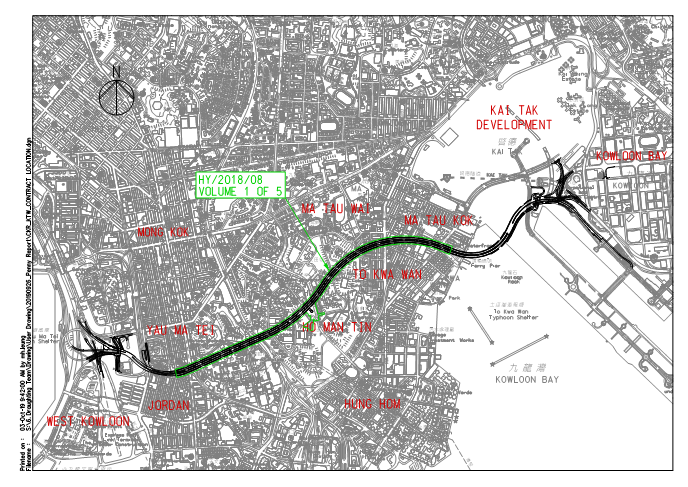

1.1.1

In

order to meet the traffic demand and relieve traffic congestion on the existing

east-west roads across Central Kowloon, Central Kowloon Route (CKR)

(hereinafter referred to as ��the Project��) is proposed which is a 4.7 km long

dual 3-lane trunk road in Central Kowloon linking Yau Ma Tei Interchange in

West Kowloon with the road network on Kai Tak Development and Kowloon Bay in

East Kowloon.

1.1.2

The

Central Kowloon Route �V Design and Construction Environmental Impact Assessment

Report (Register No.: AEIAR-171/2013) was approved with conditions by the

Environmental Protection Department (EPD) on 11 July 2013. An Environmental

Permit (EP-457/2013) was issued on 9 August 2013. Variations of EP (VEP) was

subsequently applied for and the latest EP (EP-457/2013/C) was issued by EPD on

16 January 2017.

1.1.3

Contract

no. HY/2018/08 Central Kowloon Route �V Central Tunnel (hereinafter referred to

as ��the Contract��), is one of the contracts of CKR which included the

construction of the central tunnel, cut-and-cover tunnels at Yau Ma Tei and Ma

Tau Kok and construction of piles and diaphragm walls for Ho Man Tin

ventilation building.

1.1.4

Fugro

Technical Services Limited (FTS) was appointed by Bouygues Travaux Publics

(BTP) as the Environmental Team (ET) under the Contract no. HY/2018/08) to

execute the environmental monitoring and audit (EM&A) programme under the

issued EP (EP No.: EP-457/2013/C) and in accordance with the EM&A Manual.

1.1.5

This

is the 7th Monthly EM&A Report prepared by FTS for the Contract

no. HY/2018/08 Central Kowloon Route �V Central Tunnel. The Contract no.

HY/2018/08 commenced on 19 September 2019. This report summarized the

monitoring results and audits findings of the EM&A programme under the

issued EP (EP No.: EP-457/2013/C) and in accordance with the EM&A Manual

during the reporting period from 01/03/2020 to 31/03/2020.

1.2.1

The

Project Organization structure is shown in Appendix B. The key personnel contact

names and numbers are summarized in Table 1.1.

Table 1.1 Contact

Information of Key Personnel

|

Party

|

Position

|

Name

|

Telephone

|

|

Highways Department (HyD)

|

E13/CKR

|

Mr. Joe Lam

|

2762 3380

|

|

Arup-Mott MacDonald Joint Venture (AMMJV)

|

Senior Resident Engineer

|

Mr. Ben Poon

|

3619 5967

|

|

ERM-Hong Kong, Limited (ERM)

|

Independent Environmental

Checker (IEC)

|

Ms. Mandy To

|

2271 3000

|

|

Bouygues Travaux Publics (BTP)

|

Environmental Manager

|

Mr. Simon Wong

|

9281 4346

|

|

Fugro Technical Services Limited

|

ET Leader

|

Mr. David Hung

|

3565 4371

|

1.3.1

The

construction phase of this Contract under the EP was commenced in October 2019.

The site layout plan of the Contract is shown in Figure 1.

1.3.2

The

construction programme of this Contract is shown in Appendix A.

1.4.1

The

main construction works carried out in the reporting period were as follow:

�P

Prebored H piling for ventilation shaft;

�P

Formation of site haul road leading to Chung Hau Street;

�P

Drill and Blast excavation for construction adit;

�P

Mucking out from tunnel;

�P

Construction of spoil basin;

�P

Site installation and utilities diversion;

�P

Erection of blast doors at construction adits;

�P

Removal of oversize tree T143;

�P

Trial grouting.

1.5.1

A

summary of the relevant permits, licenses and/or notifications on environmental

protection for this Contract is presented in Table 1.2.

Table 1.2 Environmental

Licenses, Notification and Permits Summary

|

Permit/ Notification/ License

|

Reference No

|

Valid From

|

Valid Till

|

|

Form NB

|

448930,

448970, 448971

|

Mid-Sep

2019

|

NA

|

|

Billing Account for Disposal of C&D

waste

|

Account

no. 7034790

|

6 Aug 2019

|

NA

|

|

Chemical Waste Producer Registration

|

5111-236-B2557-02

|

25

Sep 2019

|

NA

|

|

Construction Noise Permit

|

GW-RE1081-19

|

6 Jan 2020

|

1 Jun 2020

|

|

Construction Noise Permit

|

GW-RE0124-20

|

6 Mar 2020

|

31 Mar 2020

|

|

Water Discharge License

|

WT00034873-2019

|

22 Nov 2019

|

30 Nov 2024

|

Table 2.1

Construction Dust and Noise Monitoring Location

|

Dust Monitoring Station ID

|

Noise Monitoring Station ID

|

Monitoring Location

|

|

M-A3

|

M-N3

|

SKH Tsoi Kung Po Secondary School

|

Notes:

1. The dust and noise

monitoring station proposed in the EM&A Manual (i.e. Ko Fai House, Kwun Fai

Court with ID: M-A6/ M-N6) was not available for impact dust and noise monitoring,

therefore impact monitoring was conducted at M-A3/M-N3 as an alternative which

was agreed by the ER, IEC and EPD;

2. The coordinates of SKH

Tsoi Kung Po Secondary School can be represented as follow:

Latitude: 22.314719,

Longitude: 114.180694 (HK80 Geographical Coordinates)

Monitoring Requirement

2.2.1

In

accordance with the approved EM&A Manual, 1-hour and 24-hour Total

Suspended Particulates (TSP) levels should be measured at the designated air

quality monitoring stations to indicate the impacts of construction dust on air

quality. Regular Impact 24-hour TSP monitoring should be carried out for at

least once every 6 days, and 1-hour TSP monitoring should be done at least 3

times every 6 days when the highest dust impact occurs.

Monitoring Equipment

2.2.2

24-hour

TSP air quality monitoring was performed using High Volume Sampler (HVS) deployed

at the designated monitoring station. The HVS shall meet all the requirements

of the EM&A Manual.

2.2.3

A

portable direct reading dust meter was used to carry out the 1-hour TSP

monitoring.

2.2.4

The

model of the dust monitoring equipment used is summarized in Table

2.2.

Table 2.2 Construction

Dust Monitoring Equipment

|

Equipment

|

Brand

|

Model

|

Serial No.

|

|

High

Volume Sampler

(24-hour TSP)

|

Tisch

|

TE-5170

|

4388

|

|

Portable direct reading dust meter (1-hour TSP)

|

Sibata

|

Model LD-3B

|

647594

|

Monitoring Methodology

for HVS

2.2.5

The

following guidelines were adopted during the installation of HVS:

�P

Sufficient support is provided to secure the samplers against gusty

wind.

�P

No two samplers are placed less than 2 meters apart.

�P

The distance between the sampler and an obstacle, such as

buildings, is at least twice the height that the obstacle protrudes above the

sampler.

�P

A minimum of 2 meters of separation from walls, parapets and

penthouses is required for rooftop samples.

�P

A minimum of 2 meters separation from any supporting structure,

measured horizontally is required.

�P

No furnaces or incineration flues are nearby.

�P

Airflow around the samplers is unrestricted.

�P

The samplers are more than 20 meters from the drip line.

�P

Any wire fence and gate, to protect the sampler, should not cause

any obstruction during monitoring.

�P

Permission must be obtained to set up the samplers and to obtain

access to the monitoring stations.

�P

A secured supply of electricity is needed to operate the samplers.

2.2.6

Prior

to the commencement of the dust sampling, the flow rate of the high volume

sampler shall be properly set. The power supply should be checked to ensure the

proper functioning of the sampler. The sampler is recommended to be operated

for 5 minutes to establish thermal equilibrium before placing any filter media

at the designated air monitoring station.

2.2.7

The

filter holding frame should be removed by loosening the four nuts and placing carefully

a weighted and conditioned filter at the centre with the stamped number upwards

on a supporting screen.

2.2.8

The

filter should be aligned on the screen so that the gasket formed an airtight

seal on the outer edges of the filter. The filter holding frame should be tightened

to the filter holder with swing bolts. The applied pressure should be

sufficient to avoid air leakage at the edges.

2.2.9

A

programmed timer should be used to control the duration of operation.

Information should be recorded on the record sheet, which included the starting

time, the weather condition and the filter number.

2.2.10

After

sampling process is finished, the filter should be removed and sent to the

laboratory for weighting. The elapsed time should also be recorded.

2.2.11

All

filters should be equilibrated in a conditioning environment for 24 hours

before weighting. The conditioning environment temperature should be between

25�XC and 30�XC and not vary by more than ��3�XC; the relative humidity

(RH) should be <50% and not vary by more than ��5%. A convenient working

RH is 40%.

Maintenance

and Calibration for HVS

2.2.12

The

high volume motors and their accessories should be properly maintained,

including routine motor brushes replacement and electrical wiring checking, to

ensure that the equipment and a continuous power supply were in good working

condition.

2.2.13

Initial

calibration of dust monitoring equipment shall be conducted upon installation

and thereafter at fortnightly intervals. The transfer standard shall be

traceable to the internationally recognized primary standard and be calibrated

annually. The calibration certificate for the HVS is provided in Appendix C.

Monitoring Methodology

for Direct Reading Dust Meter

2.2.14

Portable

Laser Particle Photometer Monitors should be operated in accordance with the

Manufacturer��s instruction Manual as below:

a) Pulling up

the air sampling inlet cover

b) Changing the

Mode 0 to BG

c) Pressing

Start/Stop switch

d) Turning the

knob to SENSI.ADJ and press it

e) Pressing

Start/Stop switch again

f) Returning

the knob to the position MEASURE slowly

g) Pressing the

timer set switch to set measuring time

h) Removing the

cap and start the measurement

Maintenance

and Calibration for Direct Reading Dust Meter

2.2.15

ET

shall submit sufficient information to the IEC to prove that the instrument is

capable of achieving comparable results to the HVS. The instrument should also

be calibrated regularly, and the 1-hour sampling shall be determined

periodically by the HVS to check the validity and accuracy of the results

measured by direct reading method. The calibration certificate for the direct

reading dust meter is provided in Appendix C.

Monitoring

Requirement

2.3.1

In

accordance with the EM&A Manual, impact noise monitoring should be

conducted at the designated noise monitoring stations for at least once a week

during the construction phase of the Project. The parameters, frequency and

duration of impact noise monitoring is summarized in Table 2.3.

Table 2.3

Construction Noise Monitoring Parameters, Frequency and Duration

|

Parameter

|

Duration

|

Frequency

|

|

A-weighted

equivalent continuous sound pressure level (Leq). L10 and L90 were also recorded

|

30 minutes

|

At least once

per week

|

Monitoring Equipment

2.3.2

Noise

monitoring was performed using sound level meter at the designated monitoring

station. The sound level meters deployed comply with the International

Electrotechnical Commission Publications 651:1979 (Type 1) and 804:1985 (Type

1) specifications. Acoustic calibrator was deployed to check the sound level

meters at a known sound pressure level.

2.3.3

The

model of the noise monitoring equipment used is summarized in Table

2.4.

Table 2.4 Construction

Noise Monitoring Equipment

|

Equipment

|

Brand

|

Model

|

Serial No.

|

|

Acoustic Calibrator

|

Casella

|

CEL-120/1

|

4358443

|

|

Sound Level Meter

|

Casella

|

CEL-63X

|

4181568

|

Monitoring Methodology

2.3.4

Noise

measurement should be conducted as the following procedures:

a) Free field

measurements was made at monitoring location M-N3. A correction of +3 dB(A)

shall be made to the free field measurements.

b) The battery

condition should be checked to ensure good functioning of the meter.

c) Parameters

such as frequency weighting, the time weighting and the measurement time should

set as follow:

(i) Frequency

weighting: A

(ii) Time weighting: Fast

(iii) Measurement time: continuous

5 minutes interval

d) Prior to and

after noise measurement, the meter shall be calibrated using the calibrator for

94.0 dB at 1000 Hz. If the difference in the calibration level before and after

measurement is more than 1.0 dB, the measurement will be considered invalid and

repeat of noise measurement is required after re-calibration or repair of the

equipment.

e) The wind

speed at the monitoring station shall be checked with the portable wind meter.

Noise monitoring should be cancelled in the presence of fog, rain, and wind

with a steady speed exceeding 5 m/s, or wind with gusts exceeding 10 m/s.

f) Noise

measurement should be paused during periods of high intrusive noise if possible

and observation shall be recorded when intrusive noise is not avoided.

g) At the end

of the monitoring period, the Leq, L10 and L90 should be recorded. In addition,

site conditions and noise sources should also be recorded on a standard record

sheet.

Maintenance

and Calibration

2.3.5

Maintenance

and calibration procedures should also be carried out, including:

a) The microphone head of the sound

level meter and calibrator should be cleaned with a soft cloth at quarterly

intervals.

b) The sound level meter and

calibrator should be calibrated annually by a HOKLAS laboratory or the

manufacturer.

The

calibration certificates for noise monitoring equipment are provided in Appendix D

2.4.1

The

environmental monitoring schedule for the reporting period is provided in Appendix E.

2.5.1

The

Action and Limit Levels for construction dust and noise monitoring are provided

in Appendix F.

2.6.1

As

per the EM&A Manuals, the landscape and visual mitigation measures shall be

implemented and site inspections should be undertaken once every two weeks

during the construction period. A summary of the implementation status is

presented in Section 4.

3.1.1

The

monitoring results for 1-hour TSP and 24-hour TSP are summarized in Table 3.1 and Table 3.2

respectively. Detailed construction dust monitoring results and daily extract

of meteorological observations are presented in Appendix G.

Table 3.1 Summary

of 1-hour TSP Monitoring Results in the Reporting Period

|

Station ID

|

Average (µg/m3)

|

Range (µg/m3)

|

Action Level (µg/m3)

|

Limit Level (µg/m3)

|

|

M-A3

|

69

|

40-94

|

333

|

500

|

Table 3.2 Summary

of 24-hour TSP Monitoring Results in the Reporting Period

|

Station ID

|

Average (µg/m3)

|

Range (µg/m3)

|

Action Level (µg/m3)

|

Limit Level (µg/m3)

|

|

M-A3

|

54

|

38-74

|

153

|

260

|

3.1.2

No

Action and Limit Level exceedance was recorded for 1-hour TSP monitoring and

24-hour TSP monitoring at the monitoring location in the reporting month.

3.1.3

Major

dust sources during the monitoring included nearby traffic emission.

3.1.4

The

Event and Action Plan for the construction dust monitoring is given in Appendix I.

3.2.1

The

monitoring results for noise are summarized in Table 3.3 and the monitoring data is given in Appendix H.

Table 3.3 Summary

of Construction Noise Monitoring Results in the Reporting Period

|

Station ID

|

1Measured Noise Level, dB(A), Leq (30 mins)

|

Action Level

|

3Limit Level dB(A), Leq (30 mins)

|

|

M-N3

|

68.5�V 70.0

|

When one documented compliant is received

|

For Schools:

70dB(A) during normal teaching period and 65 dB(A) during

examination periods

|

Notes:

1. Free field noise levels were adjusted

with a correlation of +3 dB(A);

3.2.2

No

Limit Level exceedance was recorded for construction noise monitoring at the

monitoring location in the reporting month.

3.2.3

Three

(3) Action Level exceedances were recorded for construction noise due to the

noise-related complaints received in the reporting month.

3.2.4

Major

noise sources during the monitoring included nearby traffic emission.

3.2.5

The

Event and Action Plan for the construction noise monitoring is given in Appendix I.

3.3.1

Auditing

of waste management practices during regular site inspections were confirmed

that the waste generated during construction were properly, stored, handled and

disposed of in general. The Contractor was responsible for the implementation

of any mitigation measures to reduce waste or redress issues arising from the

waste materials.

3.3.2

The

implemented environmental mitigation measures for the waste management in the

reporting period are summarized in Appendix J.

The summary of observations and recommendations made for waste management during

the site inspections are presented in Table 4.1

3.3.3

Monthly

summary of waste flow table is detailed in Appendix L.

3.4.1

Bi-weekly

inspection of the implementation of landscape and visual mitigation measures were

conducted on 3, 17 and 31 March 2020. The implementation the landscape and

visual mitigation measures in the reporting period are summarized in Appendix J. The summary of

observations and recommendations made for landscape and visual mitigation

measures during the site inspections are presented in Table 4.1.

3.4.2

The

Event and Action Plan for landscape and visual during construction phase is

given in Appendix I.

4.1.1

Site

inspections were carried out on a weekly basis to monitor the implementation of

proper environmental pollution control and mitigation measures for the Project.

A summary of the mitigation measures implementation status is provided in Appendix J.

4.1.2

In

the reporting month, five site inspections were carried out on 3, 10, 17, 24

and 31 March 2020. Details of observations recorded during the site inspections

are presented in Table 4.1.

Table 4.1 Observations

and Recommendation of Site Inspection in the Reporting Period

|

Environmental Aspect

|

Date

|

Observations and Recommendations

|

Follow-up Actions

|

|

Air Quality

|

Nil

|

Nil

|

Nil

|

|

Noise

|

Nil

|

Nil

|

Nil

|

|

Water Quality

|

3 March 2020

|

The Contractor

was reminded to wheel wash within the cut off drain area and provide sandbags

near the exit gate to avoid spillage outside site boundary.

|

The item was

rectified by the Contractor on 10 Mar 2020.

|

|

31 March 2020

|

The Contractor

was reminded to provide sandbags to prevent construction run off.

-All drainage

facilities should be regularly inspected and maintained to ensure proper

operation.

|

The item was

rectified by the Contractor on 31 Mar 2020.

|

|

Waste Management

|

Nil

|

Nil

|

Nil

|

|

Landscape and

Visual

|

3 Mar 2020

|

The tree

protection zone should be enhanced

|

The item was

rectified by the Contractor on 10 Mar 2020.

|

|

Permit/ Licenses

|

Nil

|

Nil

|

Nil

|

5.1.1

No

environmental related prosecutions or notification of summons were received in

the reporting period.

5.1.2

Three

(3) noise-related complaints were received respectively on 17, 27 and 31 March

2020 via the complaint hotline of the Contract, and ET was notified of these

complaints on 8 April 2020. The complaint cases are under investigated and the

investigation results will be reported in the subsequent Monthly EM&A

Report.

5.1.3

Cumulative

complaint log, summaries of complaints, notification of summons and successful

prosecutions are presented in Appendix K.

5.1.4

No

public engagement activities were conducted in the reporting period.

5.2.1

No

environmental non-compliance was recorded in the reporting period.

5.2.2

Action

level for construction noise monitoring was triggered.

6.1.1

The

Contractor had implemented environmental mitigation measures and requirements

as stated in the EIA Reports, the EP and EM&A Manuals. The implementation

status of the environmental mitigation measures during the reporting period is

summarized in Appendix

J. Status of required submissions under the EP during the

reporting period is summarised in Table 6.1.

Table 6.1

Status of Required Submission under Environmental Permit

|

EP Condition

|

Submission

|

Submission Date

|

|

3.4

|

Monthly EM&A Report (February 2020)

|

13 March 2020

|

7.1.1

The

main works will be anticipated in the next reporting period are as follow:

�P

Formation of site haul road

leading to Chung Hau Street;

�P

Drill and Blast excavation for

construction adit;

�P

Mucking out from tunnel;

�P

Construction of spoil basin;

�P

Erection of blast doors at

construction adits;

�P

Site installation and utilities

diversion;

�P

Removal of oversize tree T143;

�P

Trial grouting.

7.1.2

The

recommended mitigation measures corresponding to the main works in the next

reporting period are listed as follow:

�P

Mitigation measures in form of regular watering under a good site

practice should be adopted, particularly for the earthwork and breaking

activities;

�P

Any excavated, stockpile of dusty material or load of dusty

materials on a vehicle leaving a construction site should be covered entirely

by impervious sheeting;

�P

All construction plants / machineries should be checked / serviced

on a regular basis during the courses of construction to minimize the emission

of noise generation and eliminate dark smoke emission;

�P

All C&D materials generated should be transported and stored at

temporary storage area. Suitable materials should be sorted for reuse on-site;

�P

Wastewater generated from drilling shall be properly collected for

reuse or treated by wastewater treatment facilities before discharge;

�P

Provision of drip trays for equipment likely cause spillage of

chemical / fuel, and provide routine maintenance;

�P

Erecting temporary noise barrier for noisy Powered Mechanical

Equipment (PME) and deployment of Quality Powered Mechanical Equipment (QPME)

as many as practicable;

�P

Mitigation measures recommended in the Landscape Mitigation Plan

shall be implemented for felling trees;

�P

Conditions in the Environmental Permit and License should be

followed;

�P

All recommended mitigation measures specified in the approved EIA

Report and EM&A Manual shall be implemented.

7.1.3

The

environmental monitoring schedule for the next reporting month is provided in Appendix E.

8.1.1

The

7th Monthly EM&A Report for the Contract no. HY/2018/08 Central

Kowloon Route �V Central Tunnel summarized the monitoring results and audits

findings of the EM&A programme under the issued EP (EP No.: EP-457/2013/C)

and in accordance with the EM&A Manual during the reporting period from 01/03/2020

to 31/03/2020.

8.1.2

Construction

dust (including 1-hour and 24-hour TSP) and noise monitoring were carried out

in the reporting period.

8.1.3

No

Action and Limit Level exceedance was recorded for construction dust monitoring

in the reporting month. No Limit Level exceedance was recorded for construction

noise monitoring in the reporting month.

8.1.4

Weekly

environmental site inspections were conducted during the reporting period. In

general, the Contractor had implemented environmental mitigation measures and

requirements as stated in the EIA Reports, the EP and EM&A Manuals.

8.1.5

Three

(3) noise-related complaints were received respectively on 17, 27 and 31 March

2020 via the complaint hotline of the Contract, and ET was notified of these

complaints on 8 April 2020. The complaint cases are under investigated and the

investigation results will be reported in the subsequent Monthly EM&A

Report.

8.1.6

Three

(3) Action Level exceedance were recorded for construction noise due to the

noise-related complaints received in the reporting month.

8.1.7

No

environmental related prosecutions or notification of summons were received in

the reporting period.

8.1.8

No

environmental non-compliance was recorded in the reporting period.

8.1.9

According

to the environmental site inspections performed in the reporting month, the

following recommendations were provided:

Air Quality

Impact

�P

No specific observation was

identified in the reporting month.

Construction

Noise Impact

�P

No specific observation was

identified in the reporting month.

Water

Quality Impact

�P

The Contractor was reminded to

wheel wash within the cut off drain area and provide sandbags near the exit

gate area to avoid spillage outside site boundary.

�P

The Contractor was reminded to

provide sandbags to prevent construction run off.

�P

All drainage facilities should

be regularly inspected and maintained to ensure proper operation.

Waste

Management

�P

No specific observation was

identified in the reporting month.

Landscape

and Visual Impact

�P

The tree protection zone should

be enhanced.

Permit/

Licenses

�P

No specific observation was

identified in the reporting month.

![]()